When Inventory Is Monitored Continuously the Safety Stock Provides Cover Agains

What is a reorder point?

A reorder indicate (ROP) is a specific level at which your stock needs to be replenished. In other words, it tells you when to identify an order so you won't run out of stock.

Significance of reorder points

If you're a business organization possessor, knowing when to club more stock is of import. If you order when you lot still have a lot of stock on hand, information technology will lead to extra stock piling upwardly, which will increment your holding costs. If you order when you have null stock on mitt, you'll be unable to make sales for as long as it takes to receive the order. The your vendor takes to supply the items, the more sales you'll be losing. Setting a reorder point helps yous optimize your inventory, replenish your stock of private items at the right time, and come across your marketplace demand without going out of stock.

How to calculate a reorder bespeak

You lot need to know when to gild each particular in your inventory separately, because different items accept different sell-through rates. To calculate the ROP for each item, you'll need to know the following parameters:

Atomic number 82 time: Time taken (in days) for your vendor to fulfill your society

Safety stock: The amount of actress stock, if any, that you keep in your inventory to help avoid stockouts

Daily boilerplate usage: The number of sales fabricated in an average 24-hour interval of that particular item

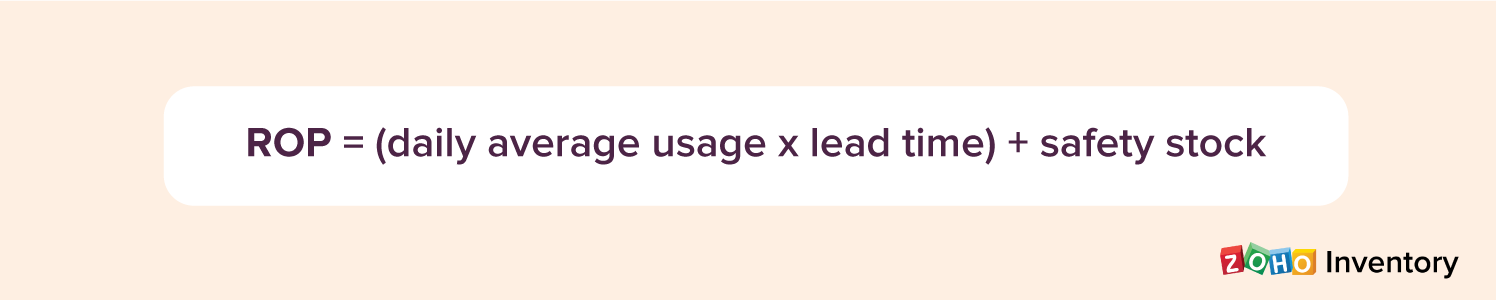

Reorder Point Formula

Let's look at how to calculate a reorder betoken both with and without safe stock. So nosotros'll comprehend how to handle reorder points when you accept multiple vendors.

- Determining ROP with safety stock

- Determining ROP without safety stock

Determining ROP with rubber stock

This method is used by businesses that keep extra stock on hand in case of unexpected circumstances. To calculate a reorder betoken with safety stock, multiply the daily average usage by the lead fourth dimension and add the amount of safety stock you go along.

Let's sympathize this with an example. Suppose you're a perfume retailer who sells 200 bottles of perfume every 24-hour interval. Your vendor takes ane calendar week to evangelize each batch of perfumes you social club. You keep plenty excess stock for five days of sales, in case of unexpected delays. Now, what should your reorder signal be?

Lead fourth dimension = seven days

Safety stock = 5 days 10 200 bottles = chiliad bottles

ROP = (200 ten 7) + thou = 2400 bottles

The order for the next batch of perfume should be placed when there are 2400 bottles left in your inventory.

Graph

This simplified reorder betoken graph shows y'all the relationship between your reorder point, stock level, and safe stock over a period of time. It helps you visualize how your reorder signal is based on your sales trends.

In the above graph, the maximum level is the sum of the prophylactic stock and the order quantity, or 3400 bottles. In one case the stock left in your inventory reaches the reorder level of 2400 bottles units, you lot should place a new buy club with your vendor. The minimum level, which is 1400 bottles, will help yous fulfill your orders until your ordered stock reaches the warehouse. Once the new order is received in your warehouse, the stock level returns to the maximum level of 3400 bottles units.

Determining ROP without rubber stock

Businesses which follow lean inventory practices or a only-in-time management strategy unremarkably don't have safety stock. In such cases, your reorder point can be calculated by multiplying your daily boilerplate sales past your lead time. Typically, when you don't have safety stock, your reorder level and the frequency of your orders tend to be higher.

Taking the in a higher place perfume example without including safe stock, your ROP should be:

ROP = 200 x 7 = 1400 bottles

Therefore, you should place an order for the next batch of perfumes when you have 1400 bottles left.

How to calculate ROP with dissimilar vendors

You lot may purchase items in your inventory from various vendors, and unlike vendors have different lead times. Therefore, it's all-time to recollect of your reorder signal on an individual item level.

For example, allow's suppose that y'all're a retailer who sells water bottles and snack boxes. The 2 items are purchased from different vendors with different lead times. The water bottles take 1 24-hour interval to go delivered (lead time = 1 solar day) and the snack boxes accept four days (lead time= 4 days). In a typical day, you sell v water bottles and ten snack boxes.

Without safety stock, your ROP with the vendor who delivers the water bottles should be:

ROP = v 10 ane = five bottles

When yous have five bottles left, that ways you have one twenty-four hour period of sales earlier you run out of stock. Since your lead fourth dimension is also one day, the new stock should arrive simply in time for y'all to continue selling without interruption.

Similarly, your ROP with the vendor who delivers the snack boxes should be

ROP = 4 ten x = twoscore boxes

Y'all should reorder when you have 40 boxes of stock left in your inventory, which is four days of stock. Given that your atomic number 82 time is also four days, the new stock should make it just in fourth dimension for you to keep selling without interruption.

A reorder point is crucial for constructive inventory management. It saves holding costs and prevents stockouts, overstocking, and lost sales past ensuring that sufficient stock is always available in your inventory.

gilmoreyouresser1972.blogspot.com

Source: https://www.zoho.com/inventory/guides/what-is-a-reorder-point.html

Postar um comentário for "When Inventory Is Monitored Continuously the Safety Stock Provides Cover Agains"